National

Cutting Tools

Home>Products>Hydraulic Pipe Threading Machine:

General Specification:

Principal Kind Gas Discussions Device comes with self starting the die go with go inventory equipment solidified with power package, with one hydraulic cylinder tube for lead attach box nut interesting, one hydraulic pipe clamping cylinder tube and one hydraulic cylinder tube for die-head starting with small changes with automated with control panel.

The Pipe Threading Machine is used for Reducing Exterior Line on Pipe joints by Pursuing method. HSS Tangential Chasers are used as blades. Pipe continues to be invitations and Die Head moves. Matric, BSP, BSPT, NPT, UNF, UNC, BSW, Acme Discussions B.S.F etc. threads can be cut on this machine based on the kind of Chasers.

The device mainly comprises the following:-

The device mainly comprises the following:-

Base

Base  Head Stock

Head Stock  Saddle

Saddle  Bed

or Pillar

Type Clamping Vice

Bed

or Pillar

Type Clamping Vice  Die

Head.

Die

Head.

THE PIPE THREADING MACHINES are developed to give highest possible performance and efficient performance under the most serious conditions of support with lowest servicing cost. All the necessary specifications are mixed in this design to from the basic principles of correct threading. All the equipment are created of case solidified metal with huge face with and teeth width and cut on hobbing machine for quiet function even at high-speed. Normally they are built with great specifications of craftsmanship, material and great quality so carefully associated with COMPANY TRADITION.

DESIGN &

WORKMANSHIP: The National Cutting Tools thread cutting machines are developed to generate great quality threads within the Lerance for which they were developed.

HEAD STOCK:

A higher great quality designed Head Box is of best great quality launching offering support to the spindle bearings. The box is of equipment type, oiled, fixed with three additional great high quality bearings.

THE BED:

The bed is pillar type having two support beams created of best great quality metal perfectly completed & properly difficult chrome coated in the most modern difficult chrome plating unit.

THE SADDLE:

The Seat is fixed on two pillers very precisely. It operates on support beams very efficiently and perfectly to the Head Stock positioning.

The APRON:

The attire gives activity to the saddle with go exchange along with support beams through metal holder and pinion preparations. It's all equipment are created of best great quality metal.

VICE JAWS:

The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle.

Range of NCT Threading Machines and Die Heads.

1/2" to 2.1/2" do/-

1" to 4" Capacity Pipe

2.1/2" to 6" Capacity Pipe

4" to 8" 4" to 8" Capacity Pipe

| Model No. | NCT-25 |

| Max. Pitch Can be Rolled (in mm) | 2.5 |

| Max. Dia can be Rolled in feed (in mm) | 25 |

| Max. Dia can be Through feed (in mm) | 16 |

| Max. Rolling Length in feed (in mm) | 80 |

| Max. Rolling Length Through feed | Indefinite |

| Max. Outer Dia Thread Rolls (in mm) | 150 |

| Spindle Dia (Bore Dia) (in mm) | 54 |

| Max. Rolling Force | 8 Tons |

| Power for Roll Spindles | 3 H.P. 1440 RPM |

| Power for Hydraulic Pump | 2 H.P. |

| Power for coolant pump | ½ H.P. |

| Model NCT-1.1/2" | 3/8"" to 1.1/2" |

| Saddle Movement | 10"-12" |

| Spindle Speed Range | 60-90 |

| Number of Spindle Speed | 2 |

| Threading Capacity | 3/8" to 1.1/2" |

| Production per Hour | 60-80 |

| H.P. Required | 3 H.P. 960 RPM |

| Lead Screw | NIL |

| Weight (KG) | 550 |

| Model NCT-2.1/2" | 1/2" to 2.1/2" (Pillar Type) |

| Saddle Movement | 12"-16" |

| Spindle Speed Range | 60-90-120 |

| Number of Spindle Speed | 3 |

| Threading Capacity | 1/2" to 2.1/2" |

| Production per Hour | 70-90 |

| H.P. Required | 7.5 H.P. 960 RPM |

| Lead Screw | As Per Requirement |

| Weight (KG) | 990 |

| Model NCT-4" | 1" to 4" (Pillar Type) |

| Saddle Movement | 10"-12" |

| Spindle Speed Range | 40-75-115 |

| Number of Spindle Speed | 3 |

| Threading Capacity | 1" to 4" |

| Production per Hour | 35-40 |

| H.P. Required | 12.5 H.P. 960 RPM |

| Lead Screw | Provided |

| Weight (KG) | 1600 |

| Model NCT-6" | 2.1/2" to 6" (Pillar Type) |

| Saddle Movement | 10"-12" |

| Spindle Speed Range | 25-50 |

| Number of Spindle Speed | 2 |

| Threading Capacity | 2.1/2" to 6" |

| Production per Hour | 20-25 |

| H.P. Required | 15 H.P. 960 RPM |

| Lead Screw | Provided |

| Weight (KG) | 1900 |

| Model NCT-8" | 4" to 8" (Pillar Type) |

| Saddle Movement | 10"-12" |

| Spindle Speed Range | 25-50 |

| Number of Spindle Speed | 2 |

| Threading Capacity | 4" to 8" |

| Production per Hour | 15-20 |

| H.P. Required | 20 H.P. 960 RPM |

| Lead Screw | Provided |

| Weight (KG) | 2500 |

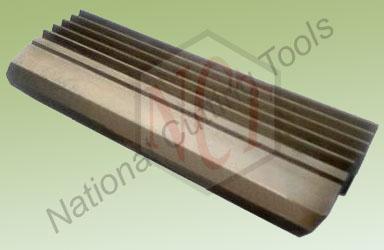

Threading Tangential Chaser

NCT Tangential Chasers are produced from brought in High Rate Steel which must successfully pass accurate metallurgical standard. Experienced warm therapy with the automated brought in warm therapy place and brought in Examining accessories, guarantees that they will perform satisfactorily in support and generate great quality threads within the patience for which they ware developed.

NCT Chaser are exchangeable. If one Pc. Of a chaser set is broken & is beyond use. Then same No. Pc. Of the other chaser set relaxing in inventory may be used and there will not be any difference in threading performance and the broken set can be changed without involve changing entire set. Read More